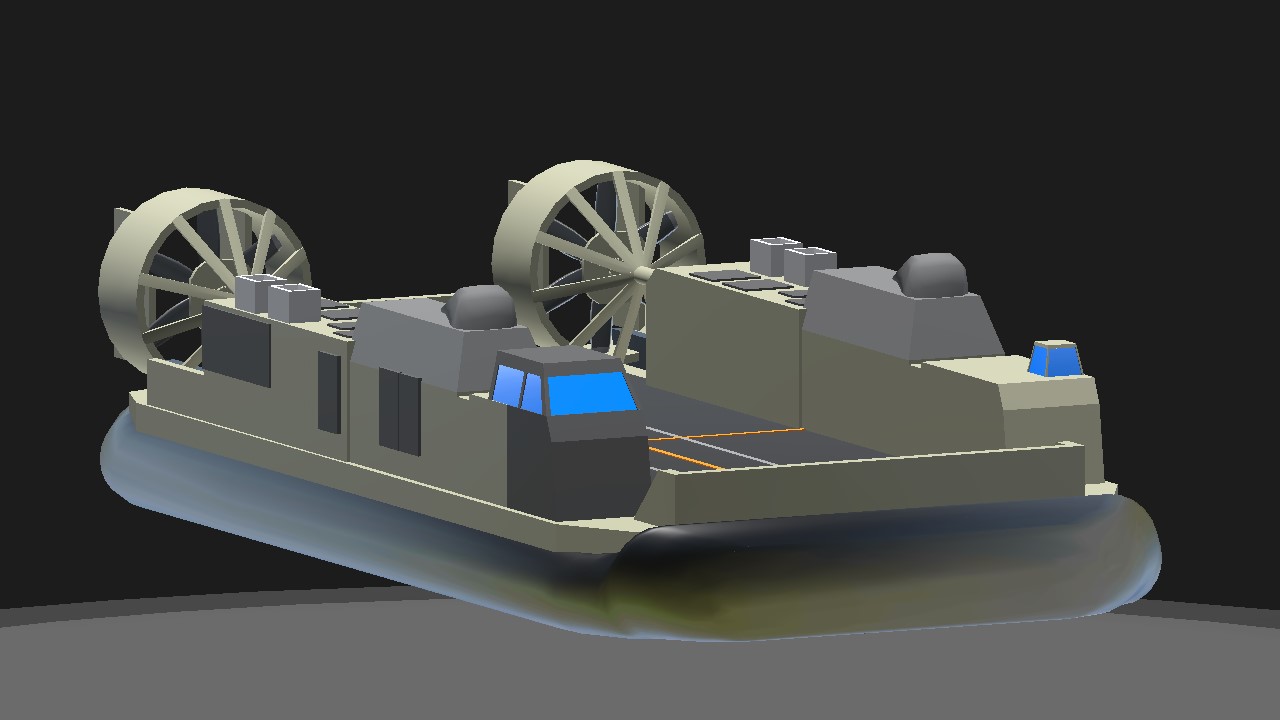

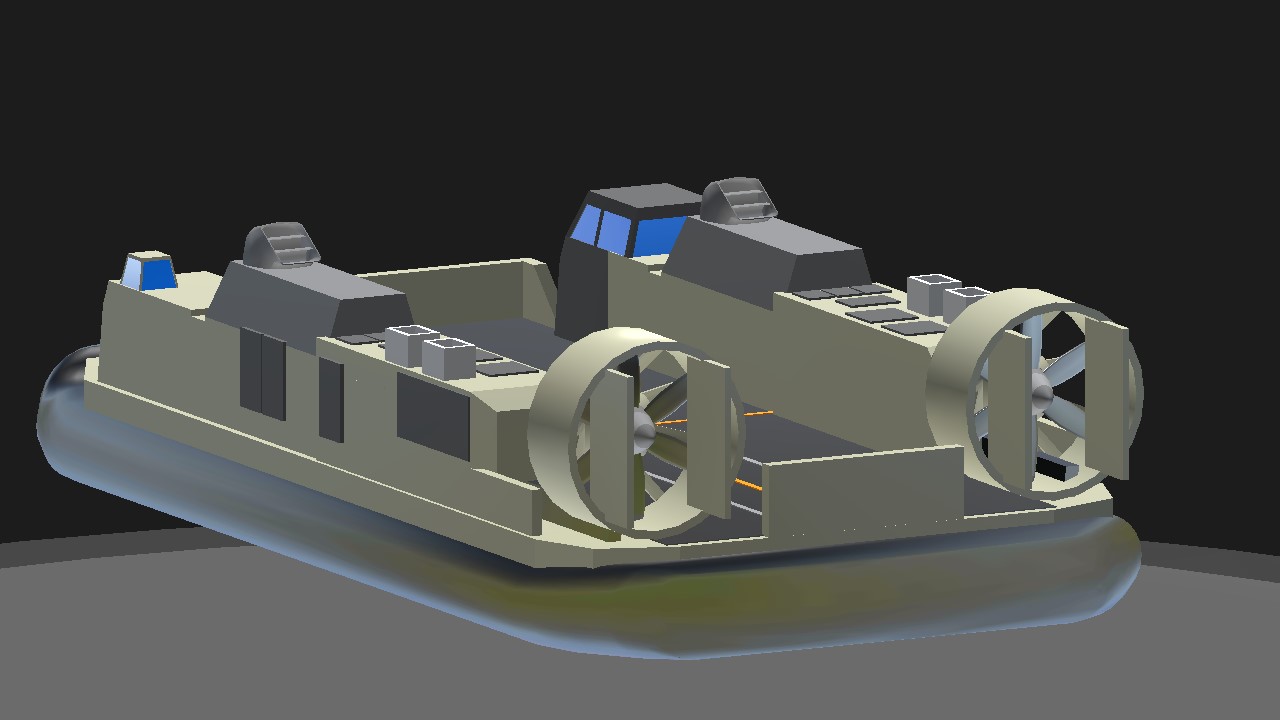

This build is not to scale with the other ships, as if it was(as I found out) it would be too small to function

The Landing Craft Air Cushion (LCAC) is a class of air-cushioned landing craft (hovercraft) used by the United States Navy and the Japan Maritime Self-Defense Force (JMSDF). They transport weapons systems, equipment, cargo and personnel from ship to shore and across the beach. It is to be replaced in US service by the Ship-to-Shore Connector (SSC).

Two prototypes were built; JEFF A by Aerojet General in California, JEFF B by Bell Aerospace.

JEFF A had four rotating ducted propellers JEFF B had two ducted rear propellers similar to the proposed SK-10 which was derived from the previous Bell SK-5 / SR.N5 hovercraft tested in Vietnam. JEFF B was selected for the LCAC. JEFF A was later modified for Arctic use and deployed in Prudhoe Bay to support offshore oil drilling.

The first 33 were included in the FY82-86 defense budgets, 15 in FY89, 12 each in FY90, FY91 and FY92, while seven were included in FY93. The first LCAC was delivered to the Navy in 1984 and Initial Operational Capability (IOC) was achieved in 1986. Approval for full production was granted in 1987.

After an initial 15-craft competitive production contract was awarded to each of two companies, Textron Marine & Land Systems (TMLS) of New Orleans, La, and Avondale Gulfport Marine, TMLS was selected to build the remaining craft. The final craft was delivered in 2001.

On June 29, 1987, approval was granted for full LCAC production. Forty-eight air-cushion landing craft were authorized and appropriated through FY 89. Lockheed Shipbuilding Company was competitively selected as a second source. The FY 1990 budget request included $219.3 million for nine craft. The FY 1991 request included full funding for 12 LCACs and advance procurement in support of the FY 1992 program (which was intended to be nine craft). The remaining 24 were funded in FY92.

Controls

- Throttle for power

- VTOL for forward and reverse movement

- Yaw to steer

Notes

- If I knew a way to simulate to air cushion deflating, I would have made it with a working ramp door.

- This is the only sea going vessel if this series that not only uses propellers as it's means of propulsion, but uses the prop engines variable propeller angle in general.

Specifications

Spotlights

- Ownedpilot 3.0 years ago

- VeryUnprofession 3.0 years ago

General Characteristics

- Predecessor War Challenge: The return of the evil (CLOSED)

- Created On Android

- Wingspan 15.6ft (4.7m)

- Length 29.3ft (8.9m)

- Height 7.1ft (2.2m)

- Empty Weight 9,098lbs (4,127kg)

- Loaded Weight 12,649lbs (5,737kg)

Performance

- Horse Power/Weight Ratio 0.093

- Wing Loading 66.9lbs/ft2 (326.8kg/m2)

- Wing Area 189.0ft2 (17.6m2)

- Drag Points 9534

Parts

- Number of Parts 121

- Control Surfaces 4

- Performance Cost 377

Too much small

im gonna try making it hover

le cacc