Background

As stated in Engine Types: Part 1 (An Introduction to Engines) I specified in a bit of detail the drawbacks and benefits of the jet engine. If you haven't read it, then shame on you... SHAME ON YOU for it is an exquisite breakdown on how engines work. I'm just kidding, I fell asleep 3 times just writing it. Obviously, the main difference between the jet engine and the piston engine is that the jet engine performs all operations required for power along a linear path.

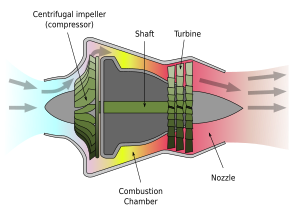

There are many ways that a jet engine can generate power, but the most common engine format is what’s known as an axial flow engine. While a cross section of a jet engine may look complicated, it is in reality quite simple in principle. Observe the graceful specimen below and the components that make up an axial flow jet engine:

Basic components of an axial flow jet engine

Compressor

The compressor is made up of rotor and stator blades inside a gradually narrowing passage, which creates pressure. Rotors are as the name suggests, the rotating portion of the compressor. These are shaped to suck air into the engine and into the combustion chamber. However, this alone doesn’t generate the level of pressure seen in modern turbine engines. As the rotor rotates, it accelerates the air, meaning pressure is lost through the kinetic energy of the air. This is where the stators come in, they help diffuse the kinetic energy generated by the rotors and convert it into static pressure.

Depiction of the rotors (rotating) and stators (static) in the compressor stage of the engine

Axial flow compressors do however, get a bit more interesting (assuming you haven’t fallen asleep reading this already). Compressors are often split into 2 sections. The Low Pressure (LP) stage and High Pressure (HP) stage (and sometimes a 3rd stage is added). These combined with the turbines are referred to as “Spools” where the HP turbine drives the HP compressor stage and the LP turbine drives the LP compressor. The reason for these stages is to improve the performance of the engine further as the more the air is compressed, the faster the rotors need to rotate in order to increase efficiency. So, you might be thinking “why not add more spools than just 3?”. Good question. The issue is that more spools mean higher complexity, meaning higher maintenance costs.

Diagram depicting a 2 spool axial flow engine

Combustion Chamber

Also known as a burner, the combustion chamber is basically a candle on steroids. A burner is made up of the following basic components:

- Diffuser – slows the high speed air entering the engine (otherwise the you risk blowing out the flame).

- Snout – separates primary and secondary air flow for the dome/swirler

- Dome/Swirler – Generates turbulence in the airflow to effectively mix the air with the fuel for ignition.

- Fuel injector – does what it says on the tin. Introduces fuel to the turbulent airflow.

- Ignitor – ignites the fuel/air mixture (only needed on start-up).

The actions from the above result in an exponential increase in pressure, which is then directed to the turbines.

Animation of a burner simulation

Turbines

Modern turbines in a jet engine are made of what can only be described as magic. They operate at temperatures that on the face of it should melt the material the turbine blade is made of. But they don’t. Hence why planes aren’t flying into the nearest hillside all the time.

So, what makes them so invincible? Science. For a start, turbine blades are basically created from a single crystal of the alloy they’re made of (by contrast, normal metal is made up of lots of crystals). This gives them unparalleled resistance to blade creep. Blade creep is basically when you spin things at really fast speeds at high temperatures, they have a tendency to elongate due to centrifugal forces (caused from spinning) and the high temperature making the blade more susceptible to being deformed.

On top of this, the turbine blades often have active cooling. A bit like how your computer processor is cooled by air cooling or a liquid cooling. Perhaps the most common method is to pump cold air into the turbine blade which then seeps out holes in the blade as depicted below, creating a protective film of cold air over the blade and preventing it from melting.

Diagram of a turbine blade

Obviously, these turbine blades are shaped to turn the velocity of the exhaust gas into a rotary motion, which then turns the compressor stages mentioned earlier. And usually stator blades make a cheeky appearance here too.

Bypass Flow

Now axial flow engines make up the majority of the engines you observe on an aircraft. SO why do all these axial flow engines look so different from each other?

The answer may surprise you.

The answer is to do with what’s referred to as the bypass ratio.

Jet engines are split into 3 categories when talking about bypass ratio.

- Turbojet (no bypass)

- Low Bypass

- High Bypass

And if you want to be really awkward, variable bypass/cycle. I’m looking at you General Electric. Anything with bypass air is generally referred to as a “Turbofan”.

Turbojets have no air bypassing the combustion chamber. Everything sucked in gets fried. Air, chickens, it all gets barbequed. In the olden days, these were the most common form of jet engine. Turbojets are generally best at operating at areas of high pressure, such as low altitudes and at very fast air speeds. For this reason, once turbofan engines entered the market, turbojets were basically swept to one side for the military to use on fighter jets and such like.

Diagram of a turbojet

Low bypass engines are the favoured brother of the turbojet. They present a happy medium between the high bypass engine and the turbojet. Again, they’re generally used more on modern military jets like the F-22 and SU-27. They allow for high altitude efficiency as well as good performance at low altitude and high speeds.

High bypass engines are usually the default for any sane aircraft company looking to make an efficient passenger jet. Any other choice is prohibited unless you’re a complete monster of a person. Often the majority of the air in these engines bypasses the combustion chamber altogether. They’re also easily identified by the huge “fan” slapped on the front of them. As with the trend, these engines are great for high altitude and slow-ish speeds. Unfortunately, due to their somewhat fat profile, they present a large source of drag, so going supersonic in these is generally not a great idea.

A Word on Centrifugal Flow

Centrifugal flow is the ugly brother of axial flow engines. They were however the true pioneers of the jet age. Instead of gradually compressing air along a linear path, they would use an impeller to throw the air violently outwards to compress it. They were however, despite their comparative inefficiencies, generally regarded as more robust than axial flow engines.

There was also a bit of an awkward stage where the two compressor types merged into what can only be described as the Frankenstein’s monster of jet engines or if you want to be more civil about it “axi-centrifugal” compressors:

The axial portion are the little blades at the “start” and the centrifugal portion is the large slab of metal in the middle, just after the little blades.

Next Time

I’ll be doing a breakdown of the remaining different types of jet engines used in the aerospace industry.

Next Post: Engine Types: Part 3 (Types of Jet Engine)

Previous Post: Engine Types: Part 1 (How Engines Work)

These things are far from boring to read.

And yes, Graingy engineers tell me that turbine blades are, in fact, magic

Hello There

Ok I just downloaded this one to make sure I will not fall asleep when I'm reading can'tvfinish it

@Squirrel lol

@Viper3000ad to answer your first question, the fuel is ignited initially via a spark, similar to how you start a piston engine. Only, because the axial flow is a continuous process, once ignited, the fuel stays ignited in the combustion chamber. Like using a match to start a candle.

@Viper3000ad I'm not 100% sure how an electric engine would qualify as a jet engine. In order to qualify an engine as a jet engine, you'd need to accelerate air to an incredibly fast speed and the only way that I'm aware of to do that effectively is by burning fuel to rapidly heat the air.

.

You can theoretically get nuclear powered jets, but they are obviously a bit of a hazard.

.

The only stand out alternatives (and I should point out I'm purely speculating from my own knowledge with no research) is to use plasma to cause a huge increase in temperature, or to somehow use a motor that as well as creates the rotary motion/speed necessary for flight while simultaneously generating a lot of excess heat to again heat the air before the exhaust.

.

Those seem a bit beyond our technical limitations at the moment though, so I can only assume that the "jet engines" you're thinking of are actually perhaps ducted fans?

Great article. I have 2 questions. The first is how a jet engine ignites the fuel in the burner? And the second, I have seen recently electric jets , if we don't have gas expanding in the burner how did they work?

@Noname918181 I'm just kidding. It's pretty difficult making things like this interesting to the casual observer. I do try and make an effort to make reading it somewhat less tedious.

@Noname918181

Squirrel wants to know your location

Interesting

Wait what happened.....

I maybe fell asleep do like.......

MORE THAN 10 TIMES