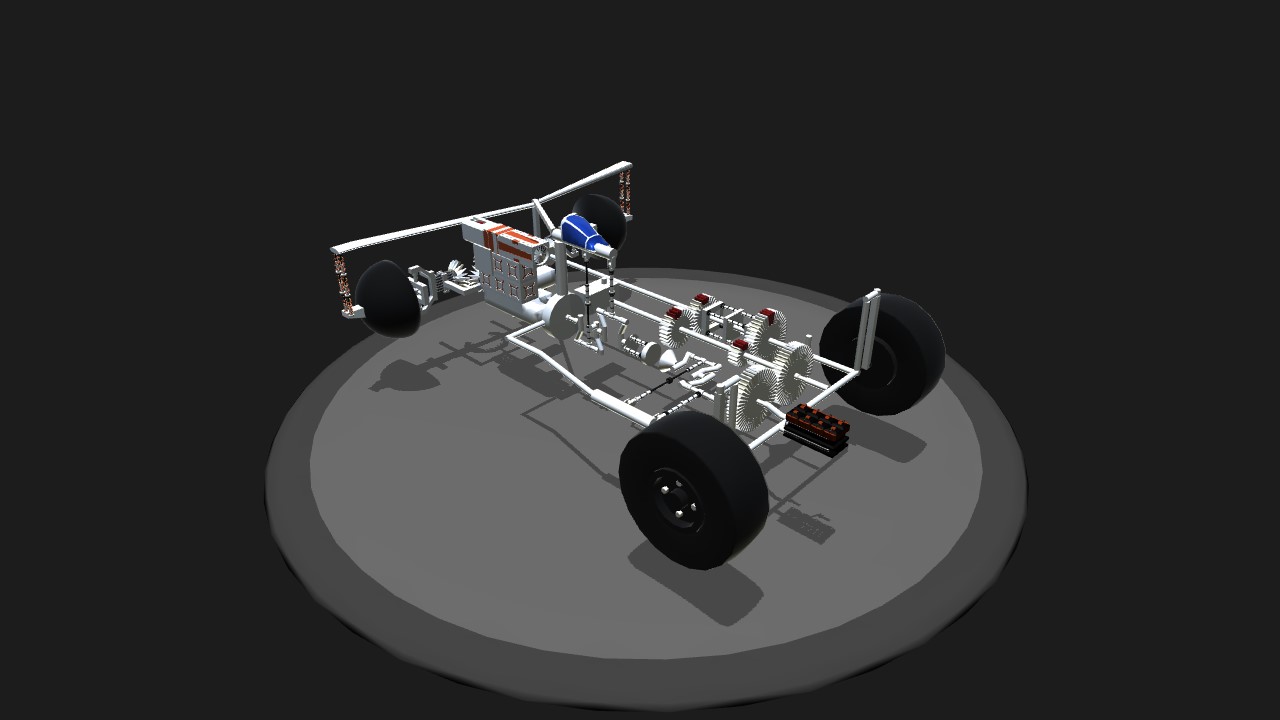

You know when we announced the Detalia Ultimate project fell through? Well, not anymore. With some clever thinking and some finger grease, we’ve finally been able to make a piston-powered ‘car’ with a gearbox.

Controls: Thrust for reverse, roll for steering.

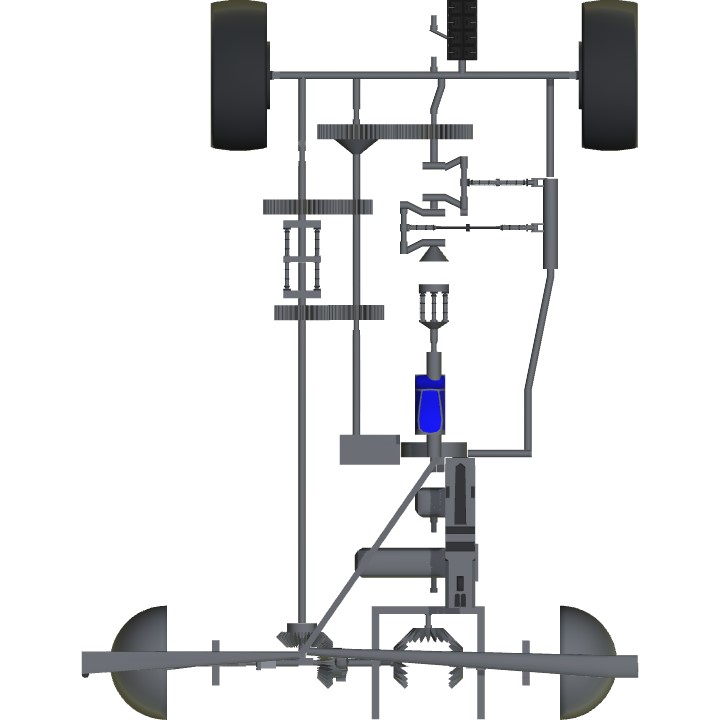

To move forward, follow these steps exactly:

1. move the VTOL slider up as little as possible and wait for the rear crankshaft to lay flat. Then, stop the engine.

2. engage AG5 and move the Trim slider up until the top of the slider is in the middle of the second arrow.

3. Disengage AG5 and bring Trim back to neutral position - the two crankshafts are now connected*.

4. Engage AG1 and bring the VTOL slider up anywhere between the 0.5 and 1.25 positions on the slider - the engine should now be functional.

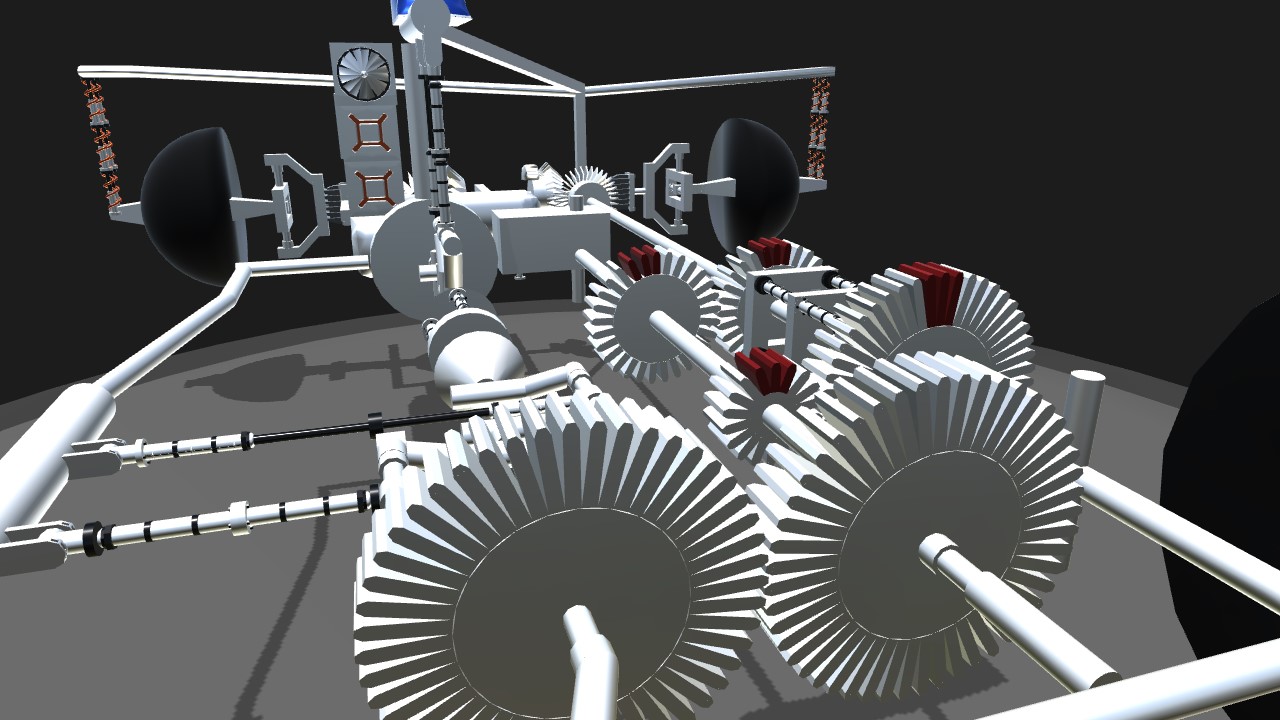

5. Gently move the Trim slider down beyond the 1.5 position. This engages first gear. I suggest you ‘clutch it’, meaning you don’t engage first gear and leave it - but engage and disengage it in quick succesion. Do this until you’re moving. The VTOL slider now determines your speed - BE GENTLE!

To change gear: Move the VTOL slider up slowly until you are at the 1.5 position. Then, disengage first gear, quickly move the VTOL slider to 0.5, and move trim slider up all the way. Second gear is now engaged. Highest safe speed is about 9MPH.

Note: the normal engine can also be used for forwards and backwards movement.

Now, allow me to explain the changes we’ve made over past designs.

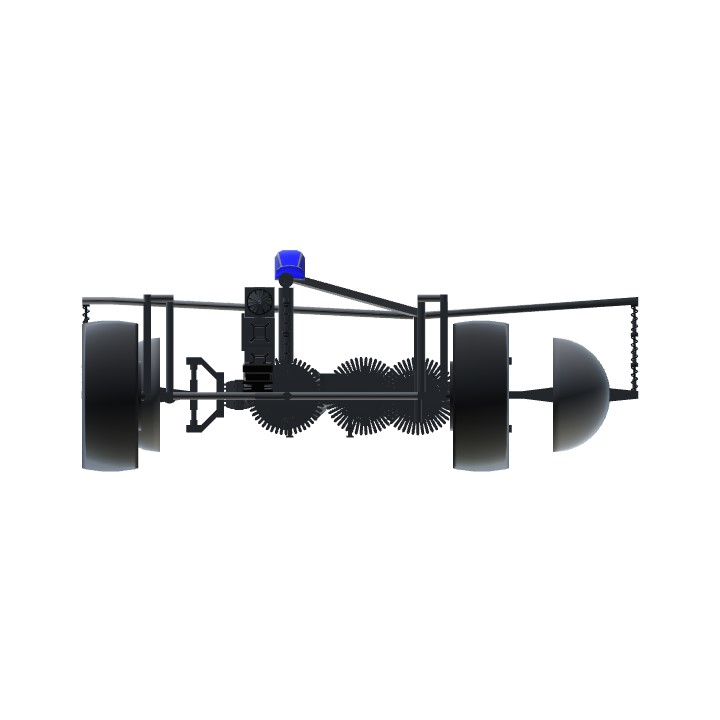

First, the gears. They are built to resemble actual straight-cut gears now. In the past, our gears were using spikes rather than properly-spaced teeth.

Secondly, structural-panel-based gears have been completely phased out. Not looking back.

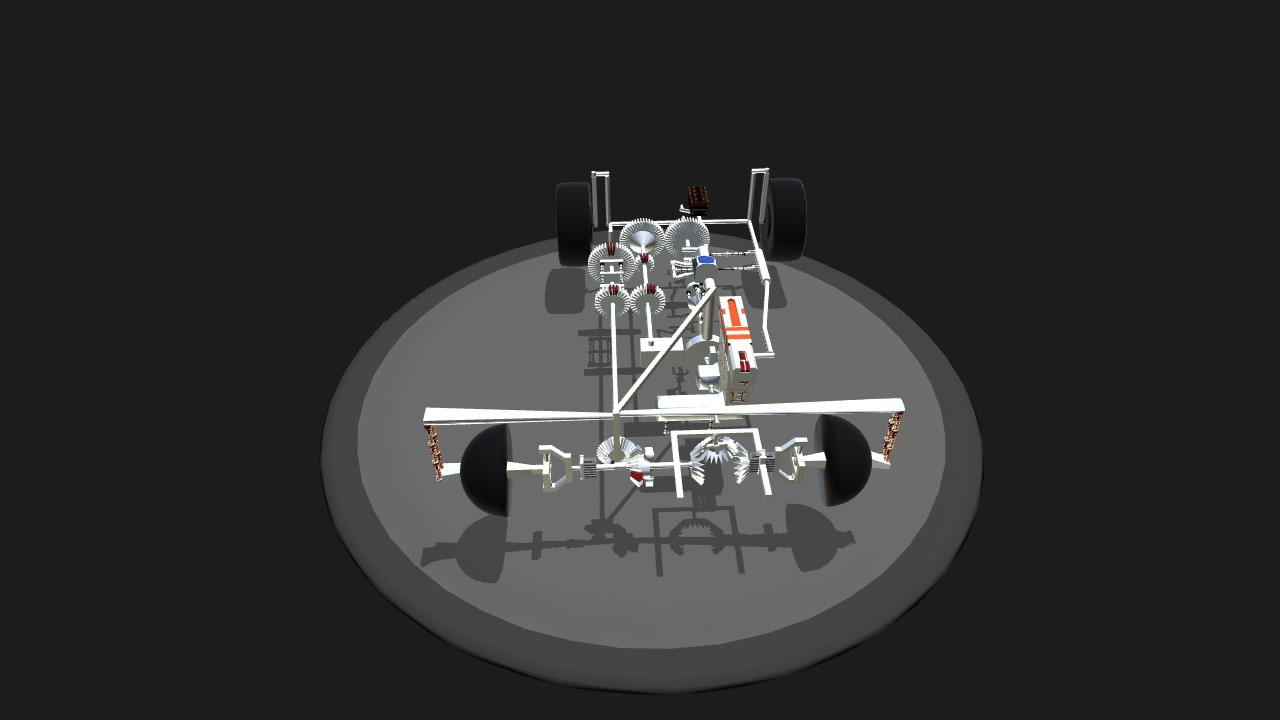

*Then, the engine itself. Previously, our piston engines relied on their own momentum to keep spinning at the end of their strokes. We could only start them by adding a weight to the side of a crankshaft. Now, we set a crankshaft to be halfway through a stroke (90 degrees), and then connect it to a second crankshaft with a clutch. This means the engine ALWAYS has power. Alternatively, this could also be achieved by placing to crankshaft next to one another and connecting them with gears, though this required a clutch still (or the moving of a whole crankshaft), and was thus dropped.

Lastly, the sort of wheels we use on the steam locomotives aren’t being used here. Instead, hemispheres are used, which are smoother (ish) and only a single part, compared to jittery and being made of around 40-50 parts each.

Specifications

General Characteristics

- Created On iOS

- Wingspan 30.3ft (9.2m)

- Length 39.2ft (12.0m)

- Height 12.0ft (3.7m)

- Empty Weight 19,279lbs (8,745kg)

- Loaded Weight 20,077lbs (9,106kg)

Performance

- Power/Weight Ratio 0.671

- Wing Loading 439,839.3lbs/ft2 (2,147,483.6kg/m2)

- Wing Area 0.0ft2 (0.0m2)

- Drag Points 14539

Parts

- Number of Parts 909

- Control Surfaces 0

- Performance Cost 3,000

NOTE:

AG5 combined with the brakes raises the back. Also, the front crankshaft is missing a rotator to keep it stable - not a big problem, but it makes everything a bit wonky. (note the different small rotators in front and behind the engine)

puts VTOL down Car: spins

@ManBoe i would love to see that. (Prolly will make my brain fizz as u said)

@imacocohehe Love to see this thing still making some impact. If only you could see what 5 years has done to my engine and gearbox designs.... Your brain would be positively fizzing

This makes my brain tingle

@TheBruh007 It sure wasn’t three months, only about one. Then again, I haven’t been very active myself due to this thing called.... a TEST WEEK.

You don’t want to know.

Hey,@ManBoe,I’m so sorry I was offline for like 3 months or something I can’t remember because I was on holidays.

Did I go too far?

Nah. I’m building gearboxes in real life as well, with LEGO parts I salvaged [ :( ] from a Technic airplane. Oh, and I hooked it up to a 40-year-old hobby steam engine for a trial run.