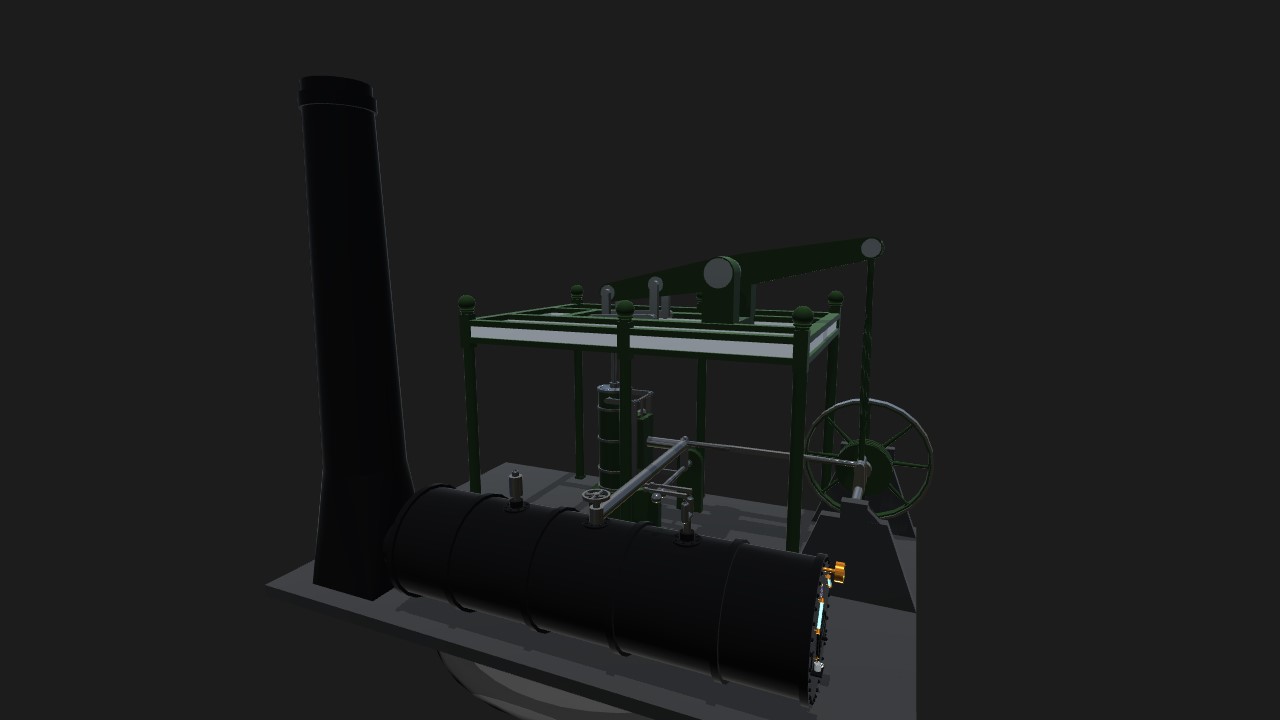

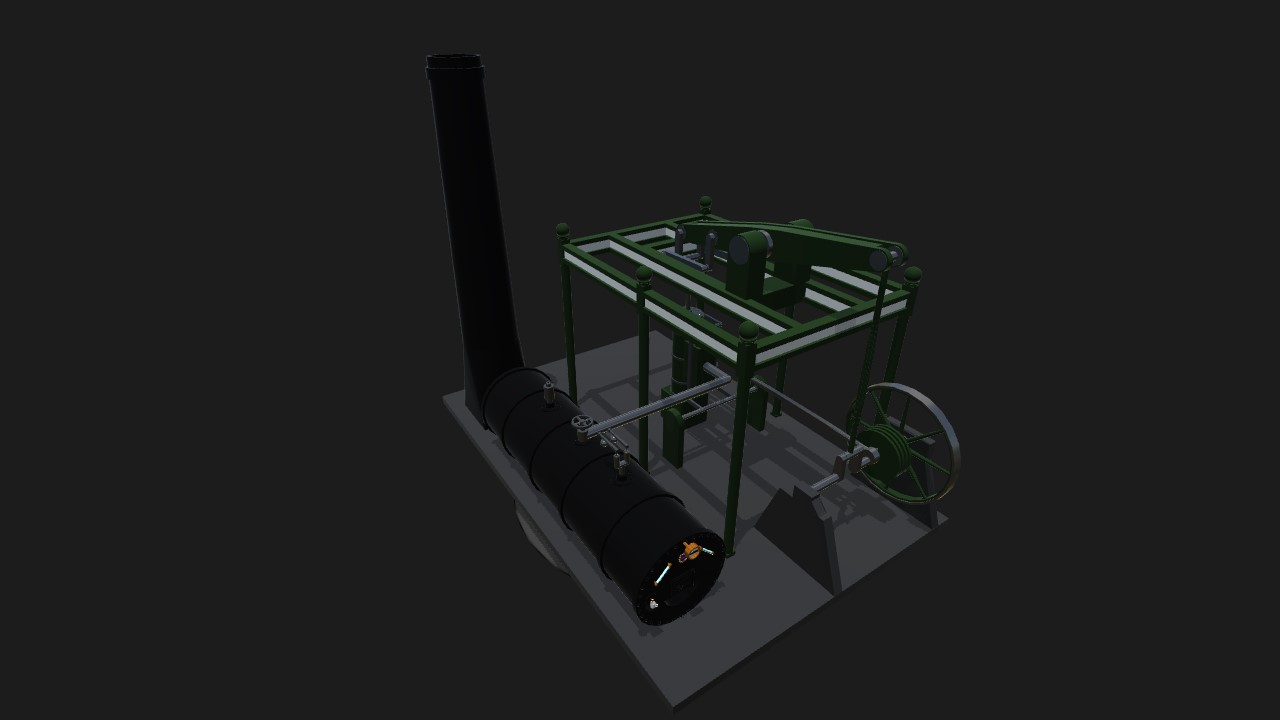

A rotative beam engine to kickstart your own industrial revolution!

This engine is based upon several engines that were built many years apart, therefore it probably wouldn't exist in this form.

The boiler (with added tea making facility) is based on the early 19th century Cornish boilers of Ritchard Trevithick, these have a single large flue through the centre of the boiler, and operate on a relatively high pressure for the time of twenty-five pounds per square inch. The first was installed at Dolcoath copper/tin mine in 1812. The boiler relies upon a characteristic large chimney to draw the heat from a cold fire through the flue to heat the water, these chimneys are still seen dotted all around Cornwall.

The boiler on this engine lacks the brick casing around the bottom half of the boiler that routed the heat from the boiler flue around the outside of the boiler before going up the chimney.

This engines boiler, like real Cornish boilers has two safety valves- One inside the boiler closest to the chimney that is adjusted to release pressure by the boilermaker, and the lever arm safety valves closest to the firehole which could be adjusted by the engineman. The one inside the boiler was set to a pressure close to maximum pressure and was added after an engine exploded in 1803 at Greenwich, after the boy who was taught to operate the manual valves decided to go eel fishing while the engine was under steam.

After 1806 all Trevithick's boilers had dual safety valves to prevent accidents like this.

The engine itself is a single cylinder design that transfers its reciprocating motion through James Watt's parallel motion linkage to a very heavy beam (here supported by an iron frame, but most were built into an engine house) this beam transfers its motion into rotative motion via a crank that is attached to a belt drum and a flywheel. The flywheel helps maintain a steady rotary motion needed for powering machines, and the belt drum would drive leather belts to power said machines. Also running of the main driveshaft is the valve gear that times the enterance of steam into the cylinder, in earlier engines valves were operated from the beam pushing a rod down against valve levers, but later the valves were typically powered off the drive shaft in a manner similar to here.

Controls:

Throttle

Why would one need anything else?

Luddites beware!

Specifications

Spotlights

- 324 5.2 years ago

General Characteristics

- Successors 1 airplane(s)

- Created On Windows

- Wingspan 55.8ft (17.0m)

- Length 83.7ft (25.5m)

- Height 67.3ft (20.5m)

- Empty Weight 190,280lbs (86,309kg)

- Loaded Weight 347,253lbs (157,511kg)

Performance

- Wing Loading 14,338.2lbs/ft2 (70,005.3kg/m2)

- Wing Area 24.2ft2 (2.3m2)

- Drag Points 150812

Parts

- Number of Parts 744

- Control Surfaces 0

- Performance Cost 2,257

Oh crap. The valve system doesn’t move enough to make the stroke work, so I’m going to need to build my own

@BurkeEnterprise Do what you like, I'm very interested in this VTOL piston concept.

Nice! I’m currently working on an engine that works by directing VTOL thrust up and down instead of the current games relatively shitty pistons. I might consider converting your engine into that if you’d like