AG1-Pantograph1

AG2-Pantograph2

Trim for thrust

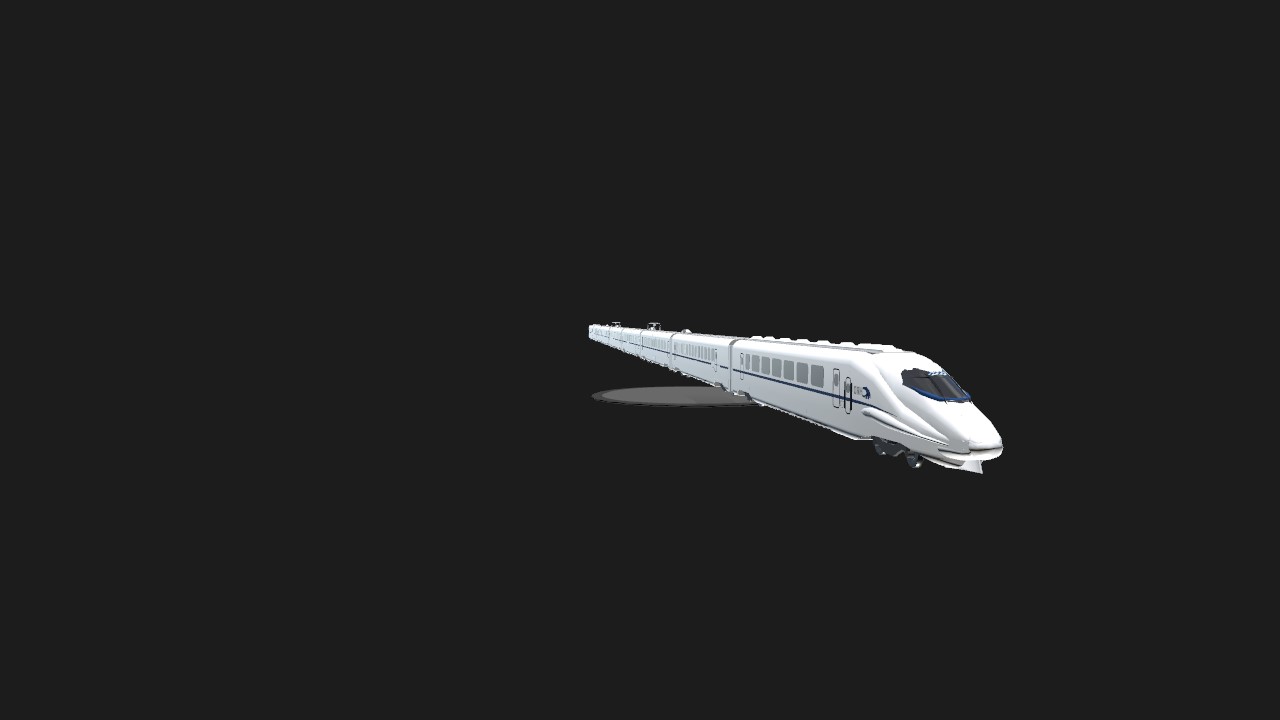

About CRH2A

Crh2a EMU is the prototype of E2 series 1000 train of Shinkansen in Japan. Through the strategy of "introduction, absorption and re innovation", China has introduced and absorbed the advanced technology of the Japanese enterprise Consortium (composed of Kawasaki heavy industry, Mitsubishi Corporation, Mitsubishi Electric, Hitachi production Institute, Itochu Corporation and Marubeni), and the former CSR Qingdao Sifang locomotive and rolling stock Co., Ltd. has achieved localization in China.

In April 2004, China's State Council held a meeting to study issues related to railway rolling stock equipment, put forward the basic principle of "introducing advanced technology, joint design and production and building Chinese brand", and established the project operation mode of introducing a small amount of original packaging, partial domestic parts assembly and mass domestic production.

The Chinese side initially negotiated with the Japanese vehicle manufacturing (NiCr) and Hitachi manufacturing with 700 series and 800 Series technologies, but both NiCr and Hitachi indicated that they refused to transfer technology to China. Later, the Chinese side waved to Kawasaki heavy industry, which cooperated with Qingdao Sifang. At that time, Kawasaki heavy industry's sales performance was not as expected, so it wanted to sell three groups of E2-1000 series and its vehicle technology to China to improve its performance.

Kawasaki's sale of Shinkansen technology to China was initially opposed by the East Japan passenger railway (JR East Japan), CSR and Hitachi. After a round of negotiations, Kawasaki sold E2 series 1000 vehicles and technology to China without the opposition and approval of many Japanese companies.

In August 2004, the former Ministry of Railways launched the first round of bidding for the introduction of high-speed EMU technology for the sixth speed increase and 200 km / h of China's railway. Six enterprises from Japan, including Kawasaki heavy industry, Mitsubishi Corporation, Mitsubishi Electric, Hitachi Manufacturing Institute, Itochu Corporation and Marubeni, formed a "Japanese enterprise Consortium" and successfully bid with the former CSR Qingdao Sifang.

The prototype of crh2a is Shinkansen E2 series 1000

On October 20, 2004, Kawasaki heavy industries, on behalf of the "Japanese enterprise Consortium", signed a contract with the Ministry of Railways of China for the export of railway vehicles and the transfer of technology, with a total value of 9.3 billion yuan. The first batch of 60 EMUs with a speed of 200 kilometers per hour in the order was then officially finalized as crh2a (crh2-001a ~ crh2-060a).

According to the contract, 3 of the 60 trains were completed in Japan and completely transported to China; Another 6 trains are delivered in bulk and assembled by the Chinese side; The remaining 51 groups will be produced domestically by Qingdao Sifang through technology transfer from Japan. However, some high-tech components, including IGBT VVVF traction inverter, will still use Japanese original products before China has the ability to localize them.

According to the technology transfer agreement, as the technology transferor, Kawasaki heavy industry is responsible for training about 300 people in Sifang company, including design, production, management and other positions. However, Japan has not transferred the vehicle control software and source code technology to China. If there is a problem with the software, it still needs to be solved by Japanese technicians.

On August 13, 2005, the former Ministry of Railways signed a technology transfer contract for 51 crh2a EMUs electromechanical products to Qingdao Sifang, Kawasaki heavy industry, Mitsubishi Electric, Zhuzhou Institute, Zhuzhou CSR electric and Shijiazhuang Guoxiang transportation equipment.

At the end of 2005, the former CSR Zhuzhou Motor introduced the technology of mt205 traction motor and atm9 traction transformer provided by Mitsubishi Electric of Japan and began trial production; Zhuzhou CSR era introduces IGBT traction inverter and other electrical system technologies provided by Toshiba, Japan. Zhuzhou Institute and Zhuzhou Shiling transportation equipment Co., Ltd., a joint venture with Mitsubishi, are responsible for the domestic production of traction inverter.

On November 26, 2007, four directions CSR times purchased traction inverter, auxiliary traction converter, ventilation system and train information system for CRH2C, with a total contract value of 596 million yuan. The supply period began in the first quarter of 2008 and ended in the first quarter of 2009.

On March 8, 2006, the first crh2a EMU (crh2-001a) produced in Japan arrived in Qingdao, China.

Specifications

General Characteristics

- Created On iOS

- Wingspan 9.2ft (2.8m)

- Length 644.3ft (196.4m)

- Height 14.7ft (4.5m)

- Empty Weight N/A

- Loaded Weight 261,178lbs (118,468kg)

Performance

- Power/Weight Ratio 172.09

- Wing Loading 630.2lbs/ft2 (3,077.1kg/m2)

- Wing Area 414.4ft2 (38.5m2)

- Drag Points 48712

Parts

- Number of Parts 1082

- Control Surfaces 0

- Performance Cost 4,966

114514

@Jedediah 确实

@Jedediah 哇,真好,我等死了

25K今天或下周发@Xuwenze

Thanks dude lol@TheTrainMakerBois987

@Jedediah its an even shorter word of "ok"

WHAT DO YOU MEAN OF “K”?@TheTrainMakerBois987

@Jedediah Hmmm k

I don’t know what did you mean but I like your railways:D@TheTrainMakerBois987

T

!!!我之前在吧里问过你的N700S@SchwererKreuzerPrinzEugen

我发了两个JR的,有兴趣可以来看看

等SS8弄完@Xuwenze

额,所以兄弟什么时候上25k?

Yes,but only 7 set of these EMUs are made in Japan

@DafaARK

好@LingwuCCYL

@Jedediah 太空了,可以再加两个

@Jedediah 头部的和谐号

@PaperPlaneHasDream

@Xuwenze

@LingwuCCYL

@XAircraftManufacturer

@Suubk27

Thanks for UPVOTE!!!

马上应该还会发文王(SS8-0001)@Xuwenze

哪里的字@Xuwenze

有头灯@Xuwenze

满分5分,3.5分

头灯要加一下,中文字就算了

字体有点不大对,颜色为什么要用灰色?